Introduction

A well-equipped loading dock is the heartbeat of efficient logistics, ensuring smooth transfer between trucks and warehouse floors. But with so many equipment options, how do you decide what matters most? This guide explores the key features to look for in commercial dock equipment, so you can create a dock that’s safe, durable, and tailored to your facility’s needs.

1. Durability & Heavy-Duty Construction

Commercial dock equipment takes daily punishment from forklifts, pallets, and heavy loads. Look for:

- Steel or reinforced aluminum components

- Powder-coated finishes for rust resistance

- Welded joints for strength

Tip:

Check the equipment’s capacity rating to ensure it exceeds your heaviest expected load.

2. Dock Levelers: Hydraulic vs. Mechanical

Hydraulic dock levelers:

- Easier and safer to operate (push-button controls)

- Reduce the risk of operator strain

- Smoother movement extends lifespan

Mechanical dock levelers:

- Lower upfront cost

- Require manual activation, which may not suit high-volume docks

Key feature:

Choose a leveler with a full-range toe guard to protect workers from pinch points.

3. Dock Seals & Shelters: Protect Against the Elements

These create a tight seal between the dock and truck, reducing:

- Energy loss (heating & cooling costs)

- Entry of rain, dust, and pests

Dock seals:

Foam pads that compress against the trailer sides.

Dock shelters:

Fabric structures that wrap around the truck, accommodating varying trailer sizes.

Tip:

Choose tear-resistant fabric and moisture-resistant foam for durability.

4. Safety Features to Reduce Accidents

Loading docks can be hazardous—prioritize equipment that enhances safety:

- Dock bumpers: Absorb impact and protect walls & equipment

- Vehicle restraint systems: Prevent trucks from moving during loading

- Fall protection: Dock gates or safety chains to secure open dock doors

- Anti-slip surfaces: Diamond tread plates or textured coatings on levelers

Stat:

According to OSHA, loading docks are a leading source of warehouse injuries—investing in safety pays off.

5. Energy Efficiency

A drafty dock increases energy bills and creates uncomfortable conditions. Key features:

- Insulated sectional dock doors

- Tight-sealing dock shelters

- Brush seals to close small gaps

These upgrades help maintain indoor temperature and reduce HVAC strain.

6. Ease of Maintenance & Operation

Downtime at the dock means lost productivity. Look for:

- Grease fittings for quick lubrication

- Replaceable wear parts (lips, bumpers)

- Easy-to-read control panels for hydraulic systems

Tip:

Choose equipment from brands with local service support and readily available parts.

7. Custom Sizing & Adjustability

Trailers vary in height and design. Features to look for:

- Adjustable dock levelers or edge-of-dock levelers

- Modular dock platforms to match site constraints

- Dock shelters are designed for oversized or specialty vehicles

Result:

Better compatibility with your fleet reduces loading delays.

8. Load Capacity & Impact Rating

Match equipment specs to your heaviest use:

- Dock levelers rated for standard forklift weights (usually 25,000–40,000 lbs)

- Dock bumpers with sufficient impact resistance

- Shelters rated for repeated trailer strikes

Tip:

If your operations handle mixed freight, choose higher capacity equipment to future-proof your dock.

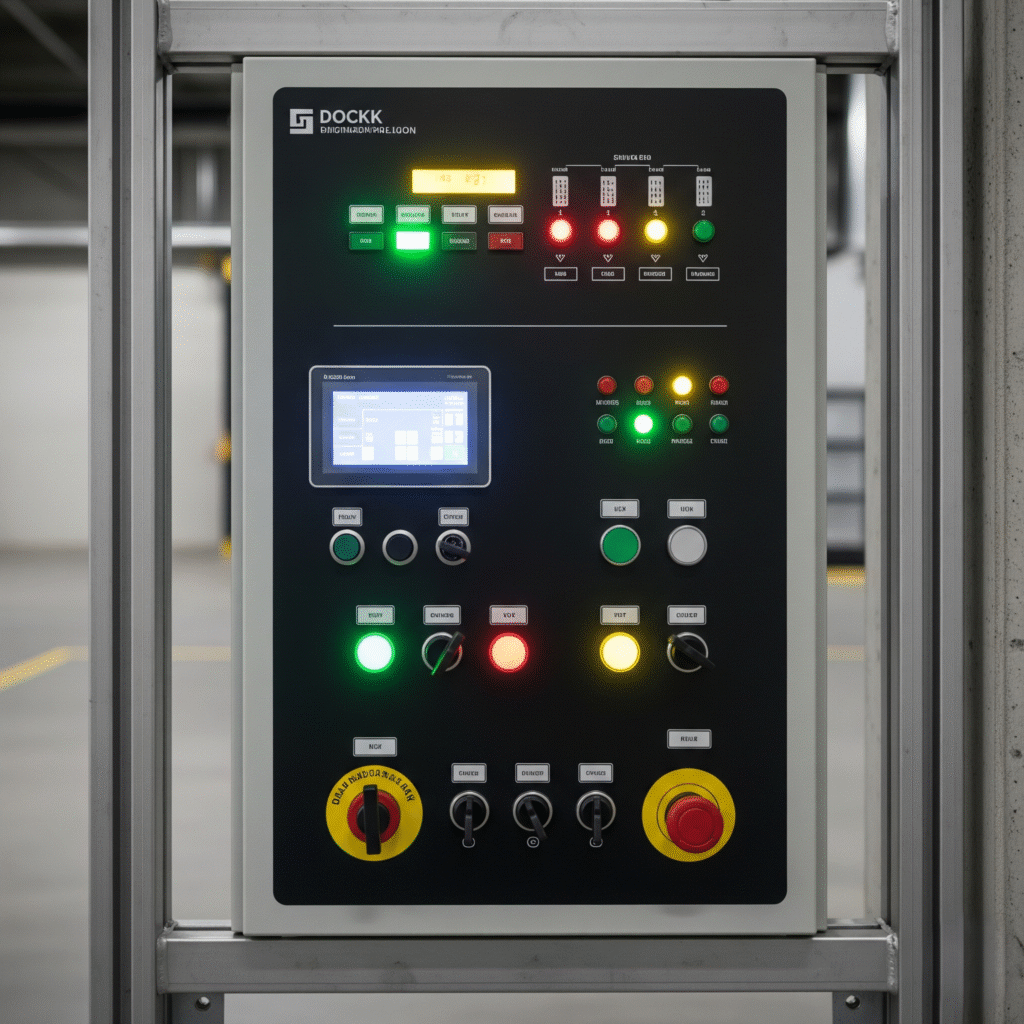

9. Technology Integration

Modern dock equipment can include:

- LED communication lights to guide drivers

- Control panels linking vehicle restraints, levelers, and doors

- Remote monitoring for maintenance alerts

These features improve safety, reduce operator error, and enhance workflow efficiency.

Conclusion

Your loading dock isn’t just a door; it’s a critical link in your supply chain. By prioritizing durability, safety features, energy efficiency, and adaptability, you create a workspace that protects staff, cuts costs, and keeps operations moving.

Before buying, consult with an experienced dock equipment contractor who understands your industry’s needs, and remember: the best equipment pays for itself in uptime, safety, and long-term savings. Contact us today!